About Us

As an Australian trademark registered and owned ignition coil brand, SWAN Ignition Coils has proven to be a specialist in the field.

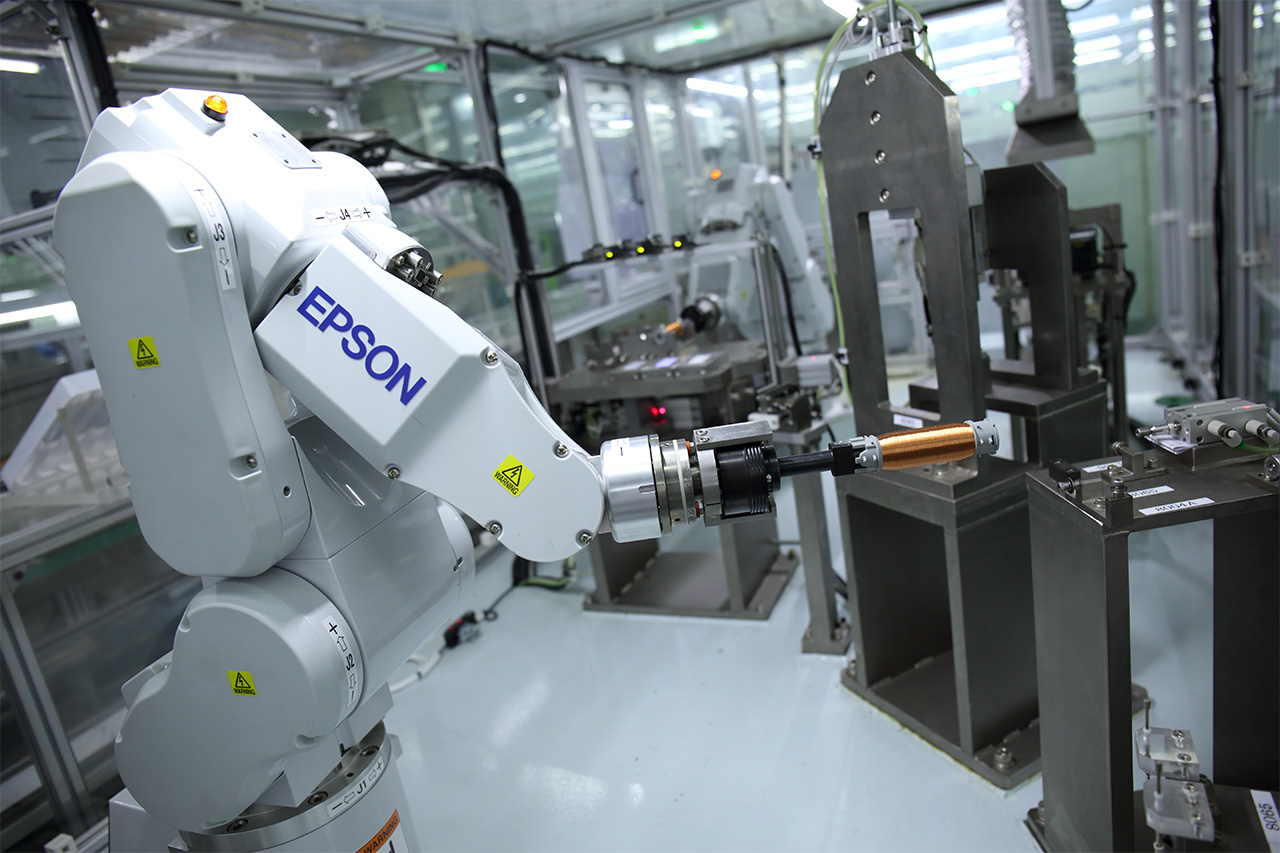

With over 15 years of product development history our ignition coils have been designed and produced by using the precision of German engineering and robotic technology to produce one of the finest quality ignition coils. You can be assured of our quality and reliability as throughout our history, we have been supplying ignition coils to mechanical workshops and automotive parts resellers Australia wide.

SWAN ignition coils are made by a world leading manufacturer that is an Original Equipment (O.E.) supplier to vehicle manufacturers around the world. They are also a supplier of major brand and aftermarket coils, which ends up covering 60% of the global market, reaching from America to Europe, Central and South America, South-East Asia and Australia.

Using our state-of-the-art research and development facility, SWAN Ignition Coils either meet or exceed the original vehicle specifications and are ISO/TS16949 quality certified.

The Epoxy Casting System that was developed in Germany is the main one used to produce our ignition coils, while the resin is sourced from Japan. In addition, our technology utilises a horizontal plastic injection machine (also manufactured in Germany), a winding and assembly cell from Italy, a thermal shock test chamber and various other pieces of sophisticated technology sourced from countries at the forefront of manufacturing. SWAN Ignition Coils exclusively use Japanese and German copper wiring for our primary and secondary spool to ensure that our coils use the highest quality raw materials.

We are members of both the Victorian Automobile Chamber of Commerce (an industry employer association that protects and promotes the interests of the automotive industry products and services sector), and the Australian Automotive Aftermarket Association (a trusted automotive association appointed by the Government to represent the automotive aftermarket parts and accessories industry).

With all stock being housed in our Melbourne warehouse and available for immediate delivery, there is no need to wait on stock arrival from third party suppliers.